How A Bowling Ball is Made

One of the most facinating processes in the bowling industry is the design and creation of custom bowling balls. Every bowling ball is specifically designed down to the molecules for an exact kind of roll down the lane. So what does this process look like? The Discovery Channel's Some Assembly Required has a brilliant segment on how a performance bowling ball is made. We'll give you the details below:

The Core

There's probably not a chocolate surprise at the center of your bowling ball.

As mentioned in the video, the core really defines the reaction of the ball to your roll. Depending on the shape, the core can have a lot or hardly any effect on hook potential depending on its shape. And while the kind of core to choose is a bowler's preference, how the core is positioned in the ball is up to the expertise of the manufacturer - especially when drilling the holes.

The Filler - Outer Core

Bowling geology.

When the core is ready to go, it's placed and centered in a cast and filled with a combination of tiny glass microbubbles and another denser filler. Different proportions of this allow the manufacturer to make the ball different weights while keeping the ball 27 inches around (within USBC specs).

The Plastic - Visible Surface

Now for the traction.The ball shaped core and filler is loaded into another mold and a paint-like plastic surface is applied by combining different molecules. This process leaves microscopic holes in the ball that catches some of the oil on the lane, allowing it to hook like it is designed.

Once that's finished, it's thrown into the oven until hardened. A quick drill for our pro shop's reference and it's time to finish up with some shine.

The Polish

Giant marble?

From here, it's just a matter of getting some consistency and speed. Smoothing out the ball and applying polish will slightly affect the ball's reaction to the lane condition. Heavily polished balls may hydroplane on well-oiled lanes but the right amount will give you a perfect combination of striking power and hook action.

And that's how the ball got to your doorstep! Now it's just a matter of getting it drilled.

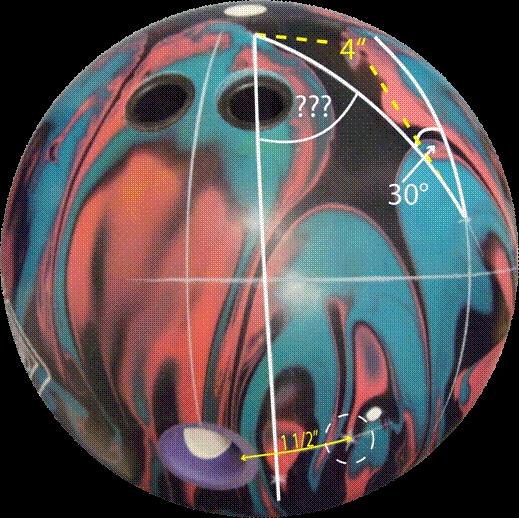

Get it Drilled!

Face it: Only a pro shop genius knows what's going on here.

The most important parts of your bowling ball are the holes, and getting the ball drilled is something a pro shop can handle for you. They'll size your hand, make the appropriate marks on the ball and presto-chango - your bowling ball is ready for the lanes!

Remember, as with any tool, a great bowling ball is only as good as its user. So practice! The ball can help you release your potential, but the skill behind it is what really matters. Always practice your fundamentals (Striking 101, Picking up the Spare), get educated on lane conditions (Understanding Oil Patterns) and watch your average get higher as you improve your game. Have fun out there!